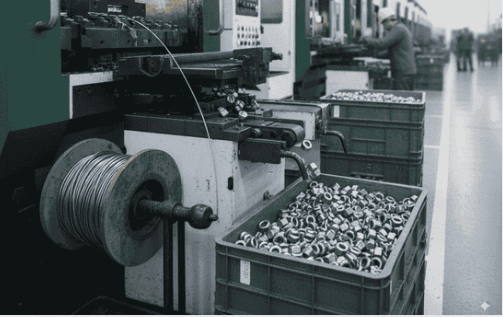

Manufacture of fasteners by cold heading

The manufacture of fasteners by cold heading has established itself as one of the most efficient and precise processes in the metallurgical industry. Thanks to this technique, it is possible to produce screws, bolts, rivets and special parts with a level of strength and finish that is difficult to achieve with other methods. In an increasingly demanding industrial market, this technology represents the perfect combination of productivity, cost savings and final quality.

What are fasteners?

Fasteners are essential components in any industry and are designed to join parts, structures or components temporarily or permanently. Their main function is to ensure that assemblies hold together, support loads, resist vibrations and meet design specifications.

From the construction of a building to the assembly of an electronic device, fasteners are the foundation that ensures the stability, safety and proper functioning of countless products and systems. Their proper choice is crucial to the durability and performance of the final assembly, so their precise and robust manufacture, such as that offered by cold heading, is of vital importance.

Materials most commonly used in the manufacture of fasteners by cold heading

One of the most important factors in the manufacture of fasteners is the choice of material.

- Cold heading steel: provides hardness, mechanical strength and durability, making it perfect for high load bearing fasteners.

- Aluminum cold heading: offers light weight and corrosion resistance, characteristics highly valued in sectors such as automotive, electronics or light construction.

The choice between steel or aluminum depends on the final application: while a steel screw can guarantee structural safety, an aluminum screw reduces weight without sacrificing efficiency.

Types of common fasteners

Screws

Screws are threaded elements designed to attach to a material, creating an internal threaded joint or coupling with a nut. They are characterized by a threaded shank and a head that allows torque to be applied for insertion or removal. They are essential for temporary or permanent assemblies, offering great versatility in the industry.

Nuts

Nuts are parts with an internal thread that attach to the threaded shank of a screw or bolt. When turned, they exert pressure against the clamping surface, securing the connection between components. They come in various shapes and designs, including safety variants to prevent loosening due to vibration.

Rivets

Rivets are permanent fasteners that join two or more parts together through plastic deformation of one or both ends. Once installed, they cannot be removed without damaging the rivet or the bonded materials. They are widely used in applications where high mechanical strength and an immovable bond are crucial.

Pins

Pins are cylindrical or tapered elements that are inserted into matching holes to align, position or fix components. They are often used to transmit shear forces or to prevent relative movement between parts. Their simple design makes them ideal for precision applications or as safety features.

Washers

Washers are flat pieces, usually circular, which are placed under the head of a bolt or nut. Their main function is to distribute the clamping load over a larger surface area, protecting the part material and preventing loosening. There are also lock washers designed to resist vibrations.

Bolts

Bolts are cylindrical fasteners without threads along their entire length or with threads at one end, designed to be used with a nut. They are usually more robust than bolts and are used in joints where higher tensile and shear strength is required. They are common in construction and heavy machinery.

Need help?

Contact our technical office and tell us about your project.

We will study your case and propose a solution to manufacture them.

Types of processes for the manufacture of fasteners by means of cold heading

In modern industry, cold heading processes for fastener production have diversified:

- Simple stamping: ideal for basic geometry fasteners.

- Progressive stamping: used for the production of fasteners that allow several operations to be carried out on the same die, thus speeding up production.

- Multi-station cold heading: an advanced method that allows complex fasteners to be manufactured in different work phases, optimizing times and reducing material waste.

The latter is especially relevant for producing high precision fasteners, bolts or industrial rivets.

Step-by-step process: how we manufacture high quality fasteners

The production of fasteners by cold heading follows a rigorous sequence that guarantees quality and precision:

- Material selection: the type of steel or aluminum is defined according to the application.

- Design and construction of dies: specific tools are developed for each type of fastening.

- Pressing and forming: the material is introduced into the press to be molded.

- Additional operations: trimming, bending, threading or punching.

- Finishing and quality control: it is verified that the fasteners comply with the required technical standards.

This process makes it possible to obtain large volumes of uniform parts, ready to meet the needs of the industrial sector.

Advantages of manufacturing fasteners by cold heading

Cold heading of fasteners offers distinct advantages over other methods:

- High production speed.

- Reduced energy consumption compared to hot stamping.

- Greater dimensional accuracy.

- Natural hardening of the material during the process.

- Reduced raw material waste.

Main applications of fasteners

Metal fasteners are often used in different types of industries and sectors such as:

- Automotive: screws and rivets for car bodies, cable terminals, and engines.

- Electronics: special screws, spacers, etc.

- Construction: high strength structural bolts, rivets and the like.

- Industrial machinery: bushings, shafts, ball joints, etc.

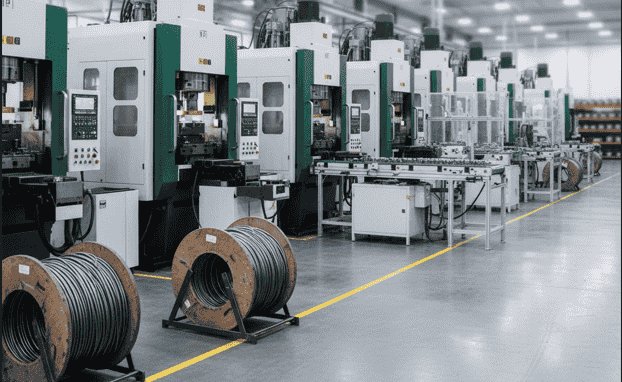

Innovation in the manufacture of metal fasteners by stamping

Innovation in cold heading applied to the manufacture of metal fasteners has occurred in two ways, on the one hand in raw materials and on the other hand in more advanced machinery.

Raw materials

Innovation in this field has allowed the development of processes capable of working with ultra-high strength steels (1500 MPa or more), used in automotive components that require maximum safety.

Machinery and dies

Similarly, multi-station stamping has made it possible to manufacture fasteners with increasingly complex geometries, reducing costs and production times without compromising quality. This has been possible thanks to advances in machinery and die development.

How to request production or quotation

If your company needs industrial fasteners by cold heading, it is advisable to contact our technical office so that we can provide you with the best solution:

- Let’s analyze your specific need.

- Select the appropriate material (steel, aluminum, etc.).

- Let’s design the necessary matrices.

- Specify finish grades, tolerances, and lead times.

Get in touch with us

Contact our technical office and tell us what kind of steel parts you need to manufacture.

We will study your case and propose a customized, fast and efficient cold stamping solution.

Frequently asked questions about fastener manufacturing by cold heading FAQ’s

Which fasteners are manufactured by cold heading?

Fasteners manufactured by cold heading are mainly screws, bolts, rivets and special fasteners for many industrial sectors.

Why is it beneficial to use high-performance steels in the manufacture of fasteners by cold heading?

Steel provides mechanical strength, durability and high load-bearing capacity, making it perfect for structural fasteners.

When should aluminum be chosen as a raw material for fastener manufacturing?

Aluminum is often used in the manufacture of metal fasteners when lightness, corrosion resistance and weight reduction are required, especially in the automotive, aeronautics and electronics industries.

What are the main process and application differences between single and multi-station cold heading in fastener production?

Simple stamping is used for basic parts, while multi-station stamping allows complex fasteners to be produced in less time and with greater precision.

Why choose LEMEC for cold heading fastener manufacturing?

Because at LEMEC we have experience, multi-station technology, top quality materials and a team specialized in designing customized fasteners that optimize your production processes.