Screws for electronics

Are you thinking about what type of fasteners to use for the manufacture of your electronic devices and you are not sure who can manufacture custom electronic fasteners? This situation is common in projects where precision, repeatability and dimensional control are critical factors from design to production.

Electronic fasteners do not respond to generic criteria. Each device requires screws with specific dimensions, suitable materials and manufacturing processes capable of guaranteeing uniformity in industrial series. Throughout this article you will find the information you need to understand what types of screws are used in electronics, how to choose the right screw according to the application and which manufacturing processes ensure the quality and tolerances required in this sector.

What is electronics hardware?

Fasteners for the electronics industry refer to the set of screws designed and manufactured specifically for use in electronic devices and equipment. Unlike standard fasteners, these screws must be adapted to small components, limited space and very specific technical requirements, where dimensional accuracy is crucial.

In the electronics industry, screws not only have a fastening function. They also influence the stability of the assembly, the protection of internal components and the ease of assembly and maintenance. For this reason, fasteners used in electronics are usually manufactured with tight tolerances, controlled materials and industrial processes capable of ensuring repeatability in series production.

In addition, many electronic projects require customized screws, either by length, diameter or head type. This makes specialized manufacturing especially relevant compared to the use of generic screws, which do not always meet the technical requirements of the sector.

Need help?

Contact our technical office and tell us about your project.

We will study your case and propose a solution to manufacture them.

What types of screws are used in electronics?

Different types of screws are used in the electronics industry depending on the component to be fastened, the material of the assembly and the mounting method. There is no single screw valid for all applications, but rather specific solutions adapted to plates, housings or internal structures of the device.

The following is a description of the most common types of screws used in electronics and their usual function within the equipment.

Small metric screws for electronics

Small metric screws are one of the most common formats in electronics. They are mainly used when the elements to be joined are prethreaded, such as metal inserts, chassis or machined supports.

Their main advantage is dimensional accuracy and the possibility of manufacturing the screw with very specific diameter and length measurements. This makes them particularly suitable for electronic devices that require repetitive and controlled assembly, both in prototypes and in mass production.

Self-tapping screws in electronic equipment

Self-tapping screws are used when the parts to be fastened do not have a previous thread, such as plastic housings or certain composite materials. When inserted, the screw itself generates the thread, simplifying the assembly process.

In electronics, this type of fastener is mainly used in external housings and secondary structural elements. Their design must be well defined to avoid damage to the material and to ensure stable fastening over time.

Printed Circuit Board (PCB) Screws

Printed circuit board (PCB) screws are used to fix and position the board inside the electronic device, ensuring mechanical stability and avoiding displacements during operation or maintenance of the equipment.

Due to the limited space and proximity to sensitive components, these screws are often defined with very specific dimensions and tight tolerances, allowing precise and repeatable assembly in industrial applications.

Screws for electronic housings and chassis

Screws for electronic housings and chassis are used to join the different structural parts of the device, protecting the internal components and facilitating access for assembly or maintenance tasks. They can be used in both metal housings and technical plastics, depending on the design of the equipment.

In industrial applications, these bolts are defined according to the housing material, the thickness of the parts and the type of assembly envisaged. Correct selection helps to improve the mechanical strength of the assembly and to maintain the integrity of the device throughout its service life.

Materials most commonly used in electronic screws

The material of the screw is a determining factor in electronic applications, as it influences the mechanical strength, corrosion behavior and compatibility with other components of the device. The material selection must be adapted to both the environment of use and the technical requirements of the equipment.

In the electronics industry, the most commonly used materials combine dimensional accuracy, stability and reliability in repetitive assembly processes.

Carbon steel and stainless steel in electronic fasteners

Carbon steel is commonly used in electronic fasteners when good mechanical strength and controlled cost are required. It is common in internal components and in applications where the environment does not present aggressive conditions.

Stainless steel, on the other hand, is used when greater resistance to corrosion or greater durability of the assembly is required. It is commonly used in devices exposed to humidity, thermal variations or demanding industrial environments.

Non-magnetic screws: brass and special alloys

Non-magnetic screws, such as those made of brass or special alloys, are used in electronic applications where it is necessary to avoid interference with magnetic fields or sensitive components. They are common in measuring equipment, precision devices and certain specific electronic systems.

In addition to their non-magnetic behavior, these materials offer good corrosion resistance and allow precise machining, making them suitable for small screws and custom fabrications in controlled series.

Surface treatments on screws for electronics

Surface treatments are applied to electronic screws to improve their performance against corrosion, wear and friction during assembly. These treatments also help to extend the screw’s service life and maintain the stability of the assembly over time.

Depending on the application, different finishes can be used, always defined according to the requirements of the electronic device and the environment of use. In industrial applications, the choice of treatment is part of the technical specification of the screw, ensuring consistency and repeatability in production.

Head and drive types for electronic equipment screws

In electronic devices, the type of head and the screw drive system directly influence the space required for assembly, ease of assembly and maintenance of the equipment. These characteristics are usually defined during the design phase, taking into account both the geometry of the device and the intended production process.

The right selection optimizes assembly, reduces errors and ensures controlled tightening, especially in series production and automated processes.

Screw head forms for electronic equipment

The most common screw heads in electronics are those that take up little space and allow good support on the surface. Among the most commonly used are cylindrical, countersunk and low-profile heads, selected according to the design of the housing or chassis.

In industrial applications, the choice of the head is made to ensure correct load distribution and proper integration with the assembly, avoiding interference with other components of the device.

Slot types and drive systems

The drive system determines how the torque is applied to the screw. In electronics, drives such as Phillips, Pozidriv, Torx or other systems designed to provide greater control and reduce the risk of slippage during assembly are commonly used.

The choice of drive is closely related to the assembly method, especially when using automatic or semi-automatic tools, where repeatability and tightening control are critical.

What is the right screw for electronics?

Determining which screw is suitable for electronics depends on the design of the device, the material of the parts to be joined and the intended manufacturing process. In industrial environments, this decision is part of the technical definition of the product and has a direct impact on the assembly, maintenance and reliability of the equipment.

When selecting hardware for an electronic device, it is important to consider the following aspects:

- Assembly and maintenance

The screw must facilitate repetitive assembly and allow disassembly without damaging components and housings, especially in equipment that requires periodic interventions. - Safety of the assembly

Correctly defined fasteners help to maintain the mechanical stability of the device, avoiding looseness, displacements or vibrations during operation. - Durability and reliability

The choice of screw influences the service life of the electronic equipment, ensuring that the fastening remains stable over time and under conditions of continuous use.

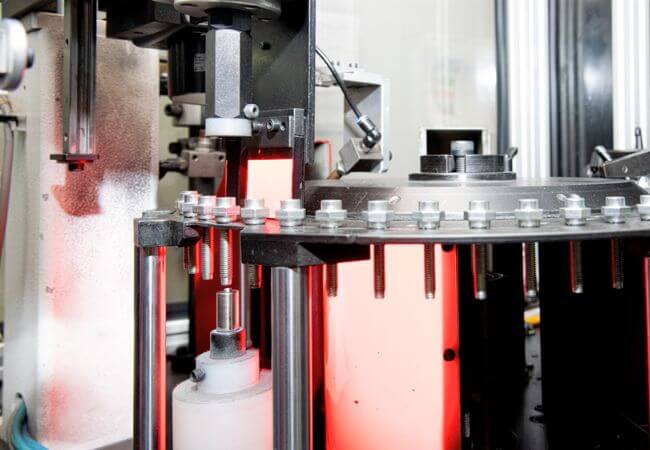

Electronics screw manufacturing: precision and bar turning

The manufacture of screws for electronics requires processes capable of guaranteeing dimensional accuracy, uniformity and repeatability, especially when working with small screws and mass production. In this context, the manufacturing method chosen is decisive to ensure that each screw complies exactly with the specifications defined in the device design.

Unlike standard fasteners, in electronics it is common for fasteners to be manufactured according to drawings or technical specifications, adapting to specific diameter, length, head or material requirements. This allows the fasteners to be integrated as a component of the product design, not as a generic element.

What is bar turning applied to electronic screws?

Bar turning is a machining process particularly suitable for the manufacture of small-sized, high-precision screws. It allows working with tight tolerances and obtaining parts with defined geometries in a very controlled way.

In electronic applications, bar turning is used when it is necessary to manufacture screws with exact measurements and homogeneous finishes, ensuring that each unit is identical to the previous one, which is essential in repetitive industrial processes.

Advantages of small screw cutting as applied to electronics

One of the main advantages of bar turning is its ability to maintain dimensional consistency over long runs. This is key in the electronics industry, where small deviations can affect the assembly or operation of the device.

In addition, this process allows a high flexibility in the design of the screw, facilitating the manufacture of tailor-made parts that adapt to the specific needs of each electronic project.

Fastener applications in the electronics industry

The fasteners used in the electronics industry are applied in a wide variety of devices and sectors, always adapting to the specific needs of each equipment. The correct screw definition guarantees mechanical stability, assembly precision and reliability in the continuous use of the device.

The following are some of the most common applications of fasteners in electronics.

Consumer electronics

In consumer electronics, screws are mainly used for fastening housings, circuit boards and internal components. They are usually small screws, defined to facilitate quick assembly and allow controlled disassembly during maintenance or repair.

In this type of device, fasteners must be integrated into increasingly compact designs, maintaining a balance between functionality, durability and ease of assembly.

Industrial and professional equipment

Electronic equipment for industrial and professional use requires fasteners with higher technical requirements. In these cases, the screws must withstand long cycles of use, vibrations and more demanding working conditions.

For this reason, it is common to use screws manufactured to technical specifications, ensuring dimensional accuracy, suitable materials and uniformity in production series.

Automation and specialized electronic devices

In automation systems and specialized electronic devices, fasteners play a key role in the stability and reliability of the assembly. This equipment often integrates sensitive electronic components and requires precise fasteners that maintain correct alignment and positioning during operation.

In this type of application, it is common to use custom-made bolts, defined according to specific design and production process requirements. Dimensional accuracy and serial uniformity are essential factors to ensure efficient assembly and consistent performance of the equipment over time.

How to choose the best manufacturer of electronic fasteners

Choosing the right electronics fastener manufacturer is a key decision when custom parts, tight tolerances and mass production are required, as it directly influences the quality of the assembly, the repeatability of the process and the reliability of the final device. To make a wise decision, it is recommended that the manufacturer meets the following criteria:

- Manufacturing capacity according to drawings or technical specifications, adapting dimensions, heads and materials to each electronic project.

- Experience in bar turning and cold heading processes, especially in small and precision screws.

- Guarantee of dimensional uniformity in series, essential for repetitive and automated assembly.

- Quality control and traceability, ensuring consistency between batches and stability of the final product.

- Knowledge of electronic applications, understanding the technical and functional requirements of the sector.

Ask for advice or quotation for the manufacture of electronic fasteners

If your electronic project requires screws with specific measurements, controlled tolerances and custom manufacturing, it is essential to have an adequate industrial process that guarantees uniformity and precision in each part.

For more information on the manufacture of special screws for electronic applications and the associated industrial processes, please visit this page:

👉 Custom screw manufacturing

Get in touch with us

Contact our technical office and tell us what kind of steel parts you need to manufacture.

We will study your case and propose a customized, fast and efficient cold stamping solution.