Types of industrial rivets

Riveting is one of the most widely used permanent fastening systems in industry because of its reliability, speed of assembly and versatility. However, not all rivets offer the same performance against vibrations, mechanical loads or material combinations, and an incorrect choice can lead to backlash, premature failure and avoidable maintenance costs.

This is where the rivet acts as a permanent and technically controllable cold fastening solution, capable of ensuring secure joints even in demanding applications where welding or fasteners are not optimal. This technical guide to applications and selection analyzes the main types of industrial main types of industrial rivetsThe guide analyzes the main types of industrial rivets, their uses by sector and the engineering criteria necessary to choose the most suitable solution, from a perspective aligned with the experience of specialized manufacturers such as Lemec.

What is industrial riveting and when to choose it as a permanent fastening system?

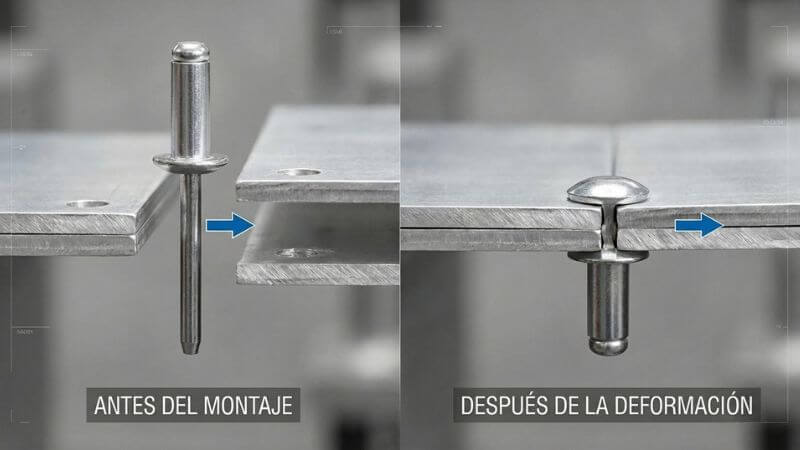

Riveting is a permanent fastening system that joins two or more parts by controlled deformation of a metal element (the rivet) without the application of heat. Unlike other joining methods, riveting makes it possible to create mechanically stable, repeatable assemblies suitable for serial industrial processes, even when working with thin sheets or dissimilar materials.

This system is especially chosen when long-term reliability, vibration resistance or when welding is not feasible for thermal, production or material reasons. Riveting is therefore common in sectors where structural safety, durability and assembly efficiency are critical factors.

Rivet, weld or screw: key differences in industrial applications

In industrial design and assembly, the choice of fastening system directly influences mechanical strength, vibration behavior, process repeatability and associated costs. Riveting, welding and bolting are common solutions, but each meets different technical requirements and must be selected according to the application.

Each fastening system responds to specific technical requirements:

- Rivet: permanent fastening, no heat input, high repeatability and excellent vibration behavior. Particularly suitable for industrial series production and heat-sensitive materials.

- Welding: rigid and continuous joint, suitable for large structural loads, although with risks of thermal deformation, greater dependence on the operator and less ease of rework or disassembly.

- Screw: removable, flexible and versatile fastening, but more prone to loosening in vibrating environments and with higher periodic maintenance requirements.

In standardized industrial applications, riveting stands out for its combination of mechanical reliability, speed of installation and long-term stability, making it a particularly efficient solution when secure and repeatable joints are required.

Mechanical advantages of industrial rivets in joints subjected to vibration

Industrial rivets are specially designed to provide reliable mechanical performance in environments subject to vibration, dynamic loads and repetitive duty cycles. As a joint obtained by controlled plastic deformation, riveting does not depend on tightening torques or threaded elements that can loosen with continued use.

In industrial applications, this feature translates into clear mechanical advantages:

- Homogeneous distribution of stresses between the joined parts, reducing stress concentrations.

- High shear strength, essential in structural assemblies and elements subjected to lateral loads.

- Long-term dimensional stability, even under constant vibration or thermal cycling.

- Reduced backlash, which reduces downtime, adjustments and corrective maintenance.

These features explain why industrial rivets are a widely used solution in sectors such as automotive, transportation, metal structures and industrial machinery, where mechanical reliability and joint durability are critical requirements.

Need help?

Contact our technical office and tell us about your project.

We will study your case and propose a solution to manufacture them.

Types of rivets according to their morphology and assembly

Rivets can be technically classified according to their morphology (body shape and design) and their method of assembly, criteria which determine their mechanical strength, the type of tool required and the field of application. This classification makes it possible to select the most suitable solution according to the required stress, the materials to be joined and the conditions of the production process.

The main types of rivets used in the industry are described below.

Solid rivets: the reference in aeronautical structures and bridges

Solid rivets consist of a solid cylindrical body and a preformed head. Their installation requires deforming the opposite end by hammering or pressing, which generates a high mechanical strength joint, especially against shear stresses.

They are used in applications where structural safety is critical, such as:

- Aeronautics

- Bridges and metallic structures

- Constructions subjected to high loads

Its main limitation is the need for access to both sides of the joint and a more demanding installation process.

Semi-tubular and tubular rivets: solutions for joints and soft materials

Semi-tubular and tubular rivets have a partial or total hole at their end, which reduces the force required for deformation during assembly. This makes them an efficient solution for mass production and materials of lower hardness.

They are common in:

- Mechanical joints

- Appliances

- Lightweight metal components

- Joints where some controlled mobility is required

They offer a good balance between ease of installation and strength, although they are not intended for high structural loads.

Impact rivets: quick installation in masonry and construction

Impact rivets are characterized by their quick installation by impact, without the need for complex tools. When the shank is inserted, it expands the rivet body, fixing it to the base material.

They are mainly used in:

- Construction and masonry

- Quick fasteners on site

- Applications where speed of assembly is paramount

Its use is oriented to non-structural fasteners, where speed is more important than maximum mechanical strength.

Blind rivets (POP type): varieties for installation from one side only

Blind rivets, commonly known as POP rivets, are designed for applications where access to only one side of the joint is available. Their assembly system, by pulling the shank, allows the rivet body to deform on the hidden face of the assembly, generating a permanent fastening in a fast and controlled manner.

This feature makes them a solution especially used in sheet metal, enclosures, profiles and industrial assemblies where subsequent access is limited or non-existent, optimizing installation times and reducing assembly costs.

Standard blind rivet: general sheet metal applications

The standard blind rivet is the most widely used for its versatility and ease of installation. It provides reliable fastening in moderate load applications and is compatible with a wide variety of materials.

It is commonly used in:

- Sheet metal

- Enclosures and panels

- Lightweight body

- Manufacturing of industrial enclosures

It is a balanced solution when speed of assembly and operational simplicity are priorities.

Watertight rivet: ensuring tightness in fluids and gases

The watertight rivet incorporates a design that prevents the passage of liquids or gases through the joint. Unlike the standard blind rivet, its geometry prevents leakage even in demanding environments.

It is particularly suitable for:

- Climate control (HVAC)

- Sealed housings and enclosures

- Applications exposed to moisture

- Systems requiring functional sealing

Its use contributes to improve the reliability of the assembly and to reduce leakage incidents.

Flower (peel) and clover rivet: special fastening for plastics and wood

The peel and trefoil rivets are designed for soft or brittle materials. During assembly, the rivet body opens at several points, distributing the load over a larger surface area.

They are common in:

- Plastics

- Wood

- Composite materials

- Lightweight panels

This controlled expansion prevents damage to the base material and improves bond strength in low density substrates.

Rivet nuts: how to create threads in thin sheets

Rivet nuts allow the incorporation of a strong thread in thin sheets or profiles where direct threading is not possible. Their installation, also from one side only, generates a permanent anchorage that accepts standard fasteners.

They are widely used in:

- Thin sheet metal

- Lightweight structures

- Assemblies requiring subsequent disassembly

- Modular manufacturing

They are a key solution when permanent fixation needs to be combined with removable functionality.

Structural rivets: high performance fasteners for heavy loads

Structural rivets are designed for applications where high mechanical performance is required, comparable in many cases to that of a welded joint. Unlike standard blind rivets, they incorporate locking systems that guarantee high tensile and shear strength, even in areas subjected to vibrations and dynamic loads.

This type of rivet is used when a high performance permanent fastening is required, with the added advantage of being able to be installed from one side in many configurations, reducing assembly times without compromising structural safety.

Internal locking mechanism and shear strength

The main difference of the structural rivets lies in their internal locking mechanism, which ensures the retention of the shank after installation. This design avoids backlash and significantly improves the mechanical behavior of the joint.

Its technical features include:

- High shear strength (shear)

- Good dynamic load and vibration behavior

- Stable and repeatable bonding

- Reduced risk of premature failure

Thanks to these properties, structural rivets are common in critical applications where reliability is a priority requirement.

Monobolt and Magna-Lok: standards in the transportation industry

Systems such as Monobolt and Magna-Lok have established themselves as benchmarks for blind structural rivets. Both offer high mechanical strength values and a locking system that guarantees long-term joint integrity.

They are widely used in:

- Rail transport

- Industrial automotive

- Heavy vehicle bodies

- Metal structures subjected to vibration

Its adoption responds to the need to combine structural safety, speed of installation and control of the production process.

Industrial applications of riveting by sector

Riveting is used transversally in many industrial sectors thanks to its ability to adapt to different materials, thicknesses and mechanical requirements. Its use not only responds to strength criteria, but also to factors such as productivity, long-term reliability and process standardization.

Some of the most representative applications by sector are listed below.

Automotive industry and car body: hybrid material bonding

In automotive and industrial bodywork, riveting makes it possible to join hybrid materials such as steel, aluminum or technical plastics, where welding can be limited or counterproductive.

It is commonly used in:

- Body panels

- Lightweight structural reinforcements

- Subassemblies subjected to vibration

High-performance structural and blind rivets are key to ensuring mechanical strength and repeatability on production lines.

HVAC and household appliances: airtight and light-weight joints

In HVAC systems and household appliances, riveting stands out for its light, fast and airtight joints, especially in metal enclosures and ductwork.

Typical applications:

- Air ducts

- Housings and panels

- Assembly of internal components

The use of watertight rivets helps to prevent leaks, improve system efficiency and reduce service incidents.

Metal construction and structures: ventilated facades and roofs

In the field of metal construction, riveting is used in solutions where speed of installation and reliability are decisive.

Applies to:

- Ventilated facades

- Metal roofing

- Enclosures and profiles

The rivets absorb expansion, maintain the integrity of the assembly and facilitate safe assembly on site, even in demanding conditions.

Engineering criteria for selecting a suitable rivet

The selection of the right rivet should not only be based on the type of product, but also on a technical evaluation of the service conditions, the materials to be joined and the mechanical stresses to which the joint will be subjected. Applying engineering criteria allows optimizing the performance of the assembly and avoiding premature failures or unnecessary oversizing.

The following are the main technical factors to be considered in a proper selection process.

Grip Range and Bore Diameter Calculation

The grip range defines the total thickness of the materials that the rivet can securely bond. Selecting a rivet outside its range compromises the correct formation of the fastener head and, therefore, the strength of the joint.

Key aspects to take into account:

- Total thickness of the assembly to be riveted

- Bore tolerances

- Rivet diameter in relation to the expected stress

Correct sizing ensures controlled deformation and a mechanically stable joint.

Material compatibility and prevention of galvanic corrosion

When joining dissimilar materials, especially metals, it is essential to consider electrochemical compatibility to avoid galvanic corrosion phenomena. The wrong choice of rivet material can accelerate the deterioration of the assembly.

Common good practices:

- Use compatible or similar materials

- Apply protective coatings

- Electrically insulate materials when necessary

This criterion is especially relevant in humid, outdoor or aggressive industrial environments.

Required strength: tensile vs shear (shear)

Every rivet should be selected according to the predominant type of stress in the application. The most common stresses are tensile and shear (shear), and not all rivets offer the same performance under both.

Technical considerations:

- Identify the main effort of the joint

- Select rivets with adequate strength values

- Prevent the rivet from working outside its optimum zone.

A correct evaluation of these efforts is key to ensure the safety and durability of the assembly.

How to work with an industrial riveting and cold heading specialist

The correct rivet selection depends not only on the product, but also on the knowledge of the process, materials and final application. In demanding industrial environments, working with a company that specializes in riveting allows optimizing the assembly design, reducing production issues and ensuring reliable mechanical performance over the long term.

With a consolidated track record in cold heading and industrial fastening solutions, Lemec assists manufacturers, engineering and technical departments in the definition of solutions adapted to each application, from the selection of the type of rivet to the technical support in the industrialization phase.

Why trust LEMEC?

LEMEC is a company specializing in the manufacture of metal parts in series by cold heading in Spain.. With an extensive track record, it offers customized solutions for demanding industrial sectors.

Services, experience and advantages

- Development and design of customized dies.

- Automated production with state-of-the-art presses.

- Wide range of typical parts and possibility of new developments.

- Advice from design to final finishing.

Contact or next steps

Get in touch with us

Contact our technical office and tell us what kind of steel parts you need to manufacture.

We will study your case and propose a customized, fast and efficient cold stamping solution.